Talking better product launch and allocation decisions with Ferrero USA

The global confectioner mitigates waste, improves service levels and controls costs by connecting digital supply chain visibility with POS analytics.

Keep readingIn both weather and retail planning, inaccurate forecasts cause mild discomfort at best and catastrophic consequences at worst. It’s not fun to come home soaking wet after a day when sunshine was predicted, and it’s bad for business when excess inventory that didn’t sell has to be marked down. At Alloy, we can’t say that we’ve fully nailed meteorology, but we do have expertise in retail forecasting and spend a lot of time leveraging best practices to benefit our clients.

When done correctly, retail forecasting relies less on guesswork and more on thoughtful data analysis. Forecasting has been around for a long time, but consumer brands that haven’t updated their methodologies are probably falling behind the competition . Yesterday’s standard procedures don’t cut it anymore in today’s retail environment.

Our Lead Data Scientist Aaron Hoffer recently wrote an article for insideBIGDATA about common mistakes brands make when preparing forecasts.

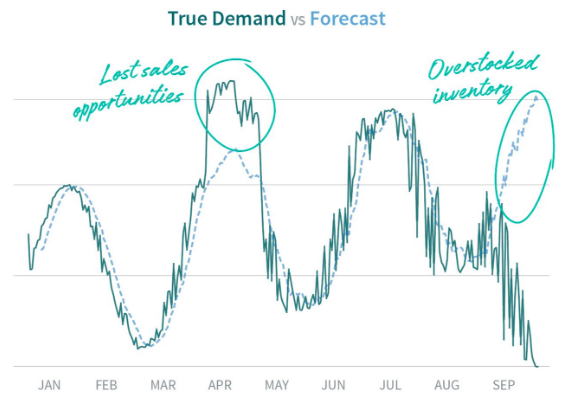

The first mistake highlighted is forecasting sales instead of store-level demand. This strategy can be harmful for two reasons:

The second forecasting pitfall is treating all misses as equal. Most cookie-cutter forecasting models will set symmetric error bounds, and if results fall outside of those bounds, it’s considered bad. While you always want your forecasts to be as accurate as possible, different misses have differing levels of severity. For instance, a produce company might view understocking apples as preferable to overstocking them, since spoiled food is a guaranteed sunk cost. Brands should customize their forecasting models to reward and penalize the specific metrics that are important for their products.

Those are two examples of don’ts in retail forecasting, but what about the dos? We’re excited to release today a new white paper that looks at the three key principles of modern forecasting for brands. They are:

In the white paper, we cover everything from data collection to explaining model results, with a focus on maximizing the usefulness of the forecast across an organization. Gone are the days when forecasting was an early and isolated step of demand planning; to remain competitive today, brands must continually keep their forecasts up-to-date and use sound data science. And even though that data science may be mathematically complex, the components and end results of a forecast should be understandable for all business units — not just the analytics team.

In the coming weeks, we’ll explore the process of successful forecasting in greater detail. In the meantime, check out our “Fundamentals of Modern Demand Forecasting” white paper for actionable tips your company can apply to improve forecasting.

The global confectioner mitigates waste, improves service levels and controls costs by connecting digital supply chain visibility with POS analytics.

Keep readingHow to take an iterative approach to digital supply chain transformation with real-time alerts that motivate teams to collaborate on issue resolution

Keep readingUnderstand how gaps between systems, teams and processes are keeping you constantly firefighting and hurting your supply chain resilience

Keep reading