Warehouse Stock Risks in Alloy.ai

- Improve fill-rates and reduce OTIF fines - Meet your supply chain KPIs by making informed decisions on production ordering, expediting production, allocation or transfers with visibility into ERP movements and retail supply levels in one place.

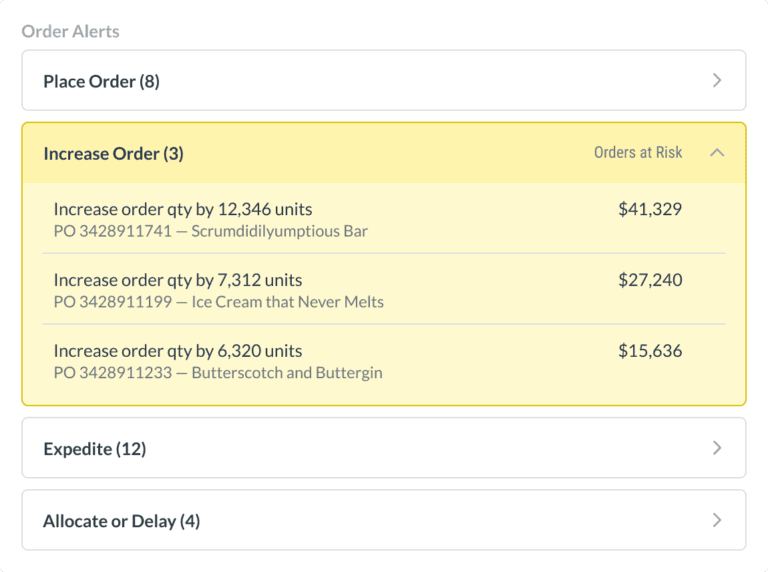

- Get recommended actions to mitigate risks - Start determining how best to address issues with specific scenario-based action recommendations in Alloy.ai.

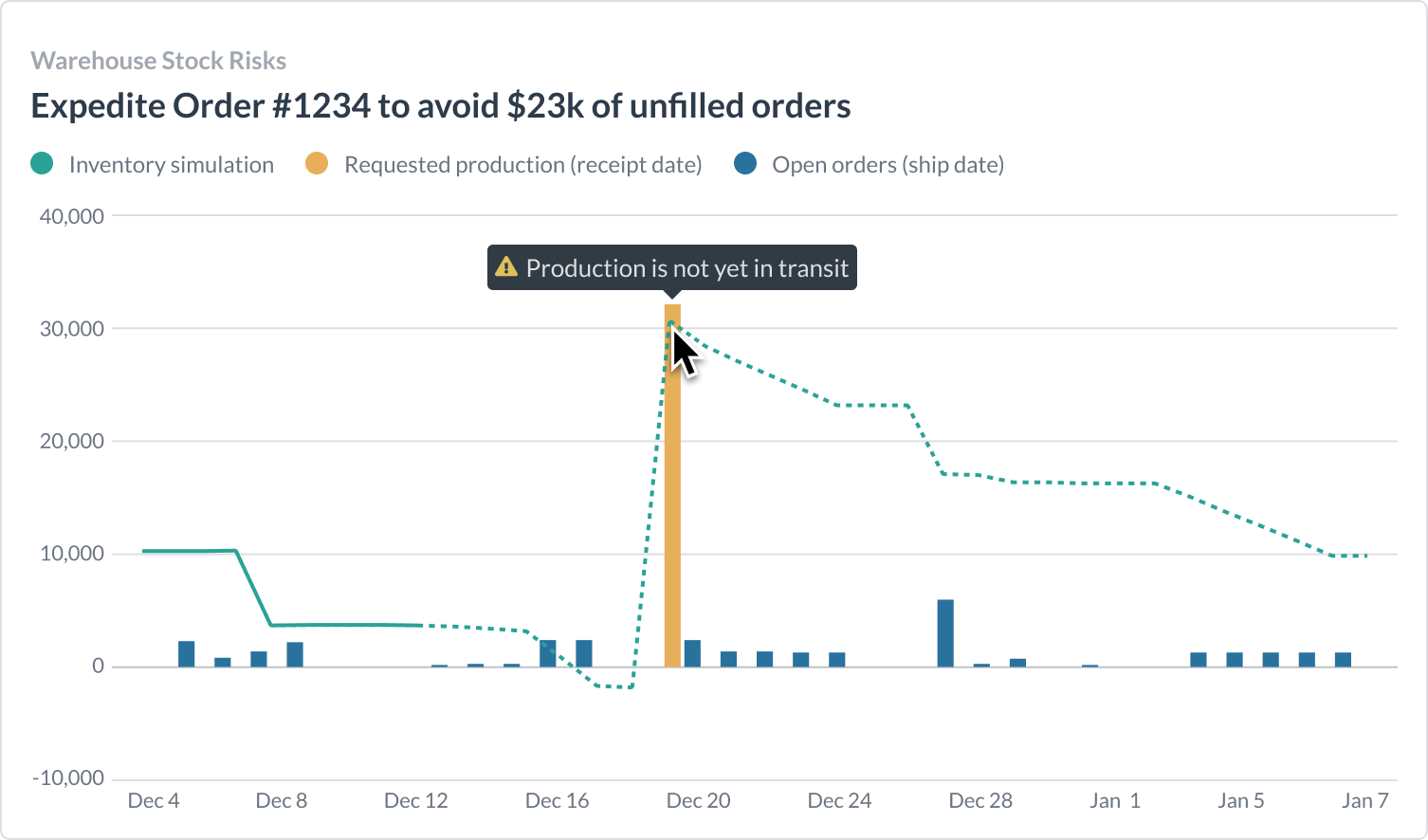

- Prioritize the biggest-impact stockout risks and take action sooner - Use simulations to identify the stockout risks that will have the greatest dollar impact and start taking action before it’s too late.

- Collaborate better with customer supply chain teams - Forewarn customer-facing teams when warehouse inventory will not be sufficient to fill orders so they can work to avoid fines and maintain good customer relationships.

Questions you can answer with Warehouse Stock Risks in Alloy.ai

- Which products in my warehouse are at risk of going OOS, or below target, in the near future?

- How much time do I have until I run out?

- How many sales are at risk?

- What will go unfilled?

- Which specific open orders?

- Are there critical inventory receipts that will lead to OOS if they don't arrive as expected?

Trusted by 100s of Consumer Brands

Identify and take action to avoid warehouse stockouts

Get Started

Frequently Asked Questions

How does Alloy.ai assist brands in improving fill rates and reducing OTIF fines?

Alloy.ai provides visibility into both ERP movements and retail supply levels, allowing brands to make informed decisions regarding production ordering, expediting production, allocation, or transfers. This comprehensive view helps meet supply chain KPIs by ensuring that inventory levels are optimized to fulfill orders on time and in full, thereby improving fill rates and reducing OTIF fines.

In what ways can Alloy.ai's simulations help prioritize warehouse stockout risks?

The platform utilizes simulations to identify stockout risks that could have the greatest financial impact. By assessing potential scenarios, Alloy.ai enables brands to prioritize and address the most critical stockout risks proactively, allowing for timely interventions before issues escalate.

How does Alloy.ai facilitate collaboration between supply chain and customer-facing teams?

Alloy.ai provides insights that allow supply chain teams to forewarn customer-facing teams about potential inventory shortages. This proactive communication enables these teams to work together to avoid fines and maintain strong customer relationships by ensuring that any inventory issues are addressed before they impact order fulfillment.