A leading fitness equipment maker hits its stride with Alloy

The speed and flexibility of Alloy POS analytics enabled this consumer brand to make more timely decisions for new product success and inventory management.

ViewNote: in this article, we’ll be referring to your forecasts as forecasts and your retailers’ forecasts as supply plans.

With supply chain headaches and inflation driving down brand loyalty, it’s more important than ever to make sure your retailers are effectively allocating your inventory.

Even if you’re a category leader, your buyer is likely relying on a machine learning-generated supply plan and can be managing upwards of 50+ other suppliers just like you. That’s why keeping a watchful eye on your partners’ supply plans for your products is crucial. You’ll quickly learn that it’s on you to make sure that their supply plan is in-line with your expectations based on historical data, market trends and your own forecasts.

We’ve compiled a list of best practices for collaborating with your retailers to make sure your forecasts are in line with their supply plans and they’re effectively allocating your inventory within their own network.

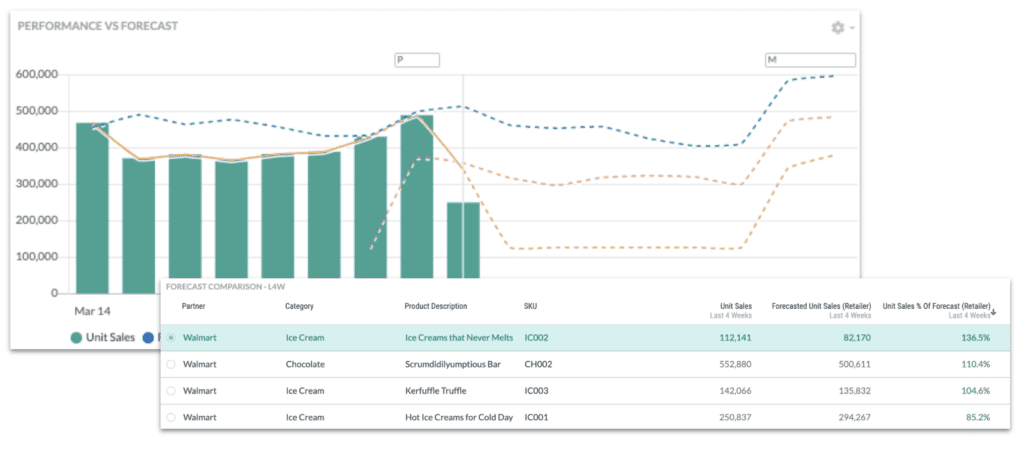

Retail forecast monitoring in Alloy

Whether you’re preparing for the holiday season, a big promotion or a weather-driven period of increased demand, you should engage and advise your retail partners on their supply plans for your products. Here are a few best practices:

Add preloaded units to lost sales and you have the actual number of units that should have been sent to that location. Finally, how does that number compare to your retailers’ supply plan for that store this year? Have your retailers accounted for those out-of-stocks?

Ultimately, you’ll wind up with a list of SKU-store combinations and a list of granular supply plan adjustments. While this type of analysis is certainly a heavy lift, acting on it with your retailer will lead to increased sales that justify the time and effort involved. You can also reverse-engineer this same exercise with the bottom 20% of unproductive stores, helping you reduce capital costs at the same time.

For fast-moving products with (relatively!) stable demand, maintaining alignment between your forecasts and your retailers’ supply plans is an ongoing battle.

Whether you’re engaged in a formal CPFR process or entering retail for the first time, you should never leave retail allocation and forecasting purely up to chance. To learn more about how to put these tactics into practice, get in touch with us today.

The speed and flexibility of Alloy POS analytics enabled this consumer brand to make more timely decisions for new product success and inventory management.

ViewThe global confectioner mitigates waste, improves service levels and controls costs by connecting digital supply chain visibility with POS analytics.

Keep readingHow to take an iterative approach to digital supply chain transformation with real-time alerts that motivate teams to collaborate on issue resolution

Keep reading