Talking better product launch and allocation decisions with Ferrero USA

The global confectioner mitigates waste, improves service levels and controls costs by connecting digital supply chain visibility with POS analytics.

Keep readingUntil now, digital supply chain technology has focused on two core needs: planning and execution. Companies can select from a diverse set of planning solutions to drive increasingly complex S&OP processes. Execution-focused software like OMS, WMS and TMS systems are standards in executing on these plans. But supply chain leaders are increasingly dissatisfied with the results of the status quo.

Shrewd supply chain managers are waking up to the reality that planning can’t predict surprises. Even after years of innovation, forecasting models still average a 30% error rate. While S&OP is still vital to align plans across your company, we believe that the gap between planning and execution is the silent killer of operational excellence.

Shrewd supply chain managers are waking up to the reality that planning can’t predict surprises.

We also understand that bridging this gap requires a human approach, where you must address the gaps between your teams, your processes and your systems. Getting this right has never been more important in the face of unprecedented demand volatility and supply disruptions. Today’s reality is that problems and opportunities are identified and addressed too late, where decisions are often made with incomplete context because data can’t be mapped and translated across systems.

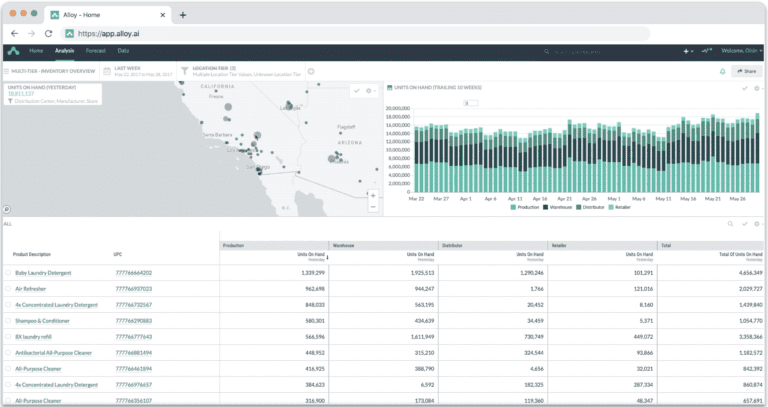

Today we are launching Inventory Intelligence, a real-time control tower built to help consumer goods companies bridge the gap between planning and execution. Our solution empowers your organization to identify risks and opportunities in real time and streamline decisions across teams.

Unlike other technologies, the Alloy Data Platform automatically maps and translates data from disparate internal and partner systems to provide upstream and downstream context for all of your decisions. Alloy ingests POS data, customer and internal inventory, orders & shipments, forecasts and plans. We align everyone around a single source of truth by providing a current, contextual view of supply and demand across your network.

Customers like Ferrero and Valvoline use Inventory Intelligence to connect real-time plan adjustments, inventory management, executive visibility, customer supply chain and sales. Thanks to the ways our customers push us to learn and develop, we’ve built a solution that’s proven to help consumer goods brands avoid lost market share, improve service levels, reduce working capital and mitigate waste.

If you’d like to learn more, check out our white paper exposing the gap between planning and execution, learn how Inventory Intelligence can help, and contact us for a demo.

The global confectioner mitigates waste, improves service levels and controls costs by connecting digital supply chain visibility with POS analytics.

Keep readingHow to take an iterative approach to digital supply chain transformation with real-time alerts that motivate teams to collaborate on issue resolution

Keep readingUnderstand how gaps between systems, teams and processes are keeping you constantly firefighting and hurting your supply chain resilience

Keep reading