Built for Consumer Brands

Crush Your Sales Supply Chain Replenishment Forecasting Data Inventory Problems

Integrations with retailer & supply chain partenrs

Of leading consumer brands run on Alloy.ai

Million active SKUs

Million locations tracked

Introducing Alloy.ai

Your One-Stop-Shop for Sales and Supply Chain Performance

Retail Data Connectors

Revenue Intelligence

Supply Chain Visibility

Artificial Intelligence

Retail & Supply Chain Data Connectors

Integrate Data From Anywhere. Use It Everywhere.

API, EDI, Retailer Portal — Whatever the source, you’ll get normalized, daily sales and inventory data from your retail partners piped directly into your data warehouse, analytics, planning app and more.

Explore Integrations:

Omnichannel Revenue Intelligence

A Clear Picture of Your Business

Powerful and flexible retail analytics — choose from 100s of pre-built CPG-specific dashboards and reports or create your own. Get alerts about stockouts, phantom inventory, replenishment opportunities and more. Drill down to specific SKUs or locations, or zoom out to see cross-retailer, cross-channel trends.

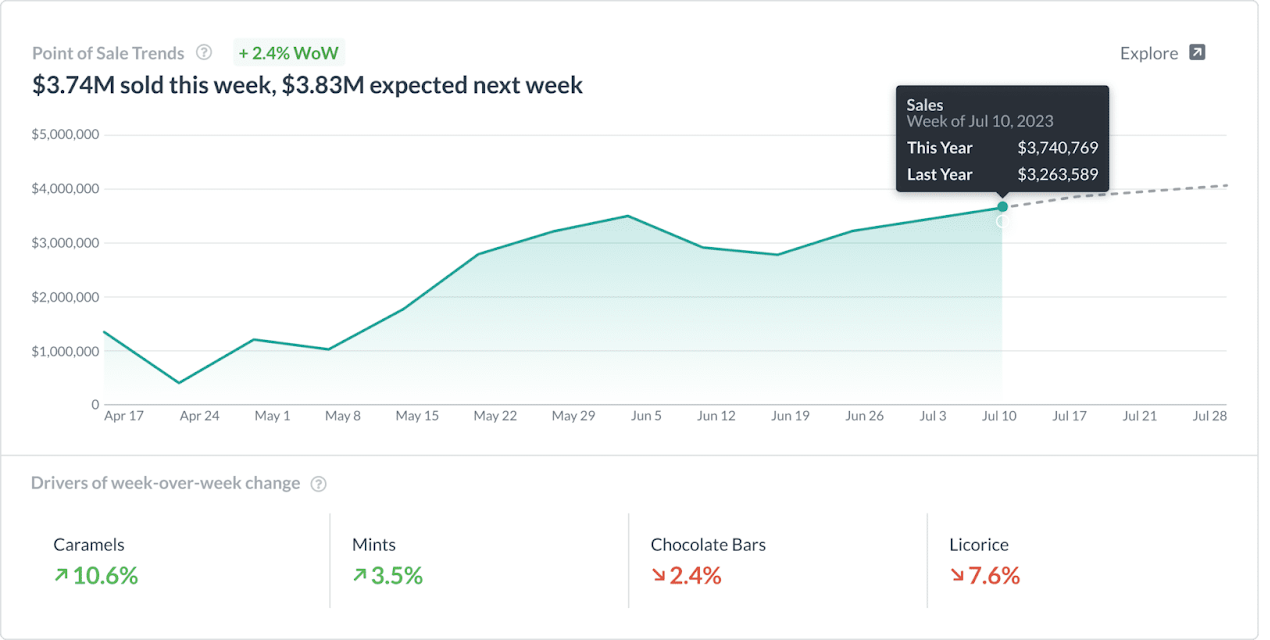

Alloy.ai surfaces up key insights, exceptions and alerts from your POS data. See real-time sales trends and inventory performance across retailers.

Get alerted to when Weeks of Supply are running low across all of your retailers and channels. Identify stockouts and take corrective action.

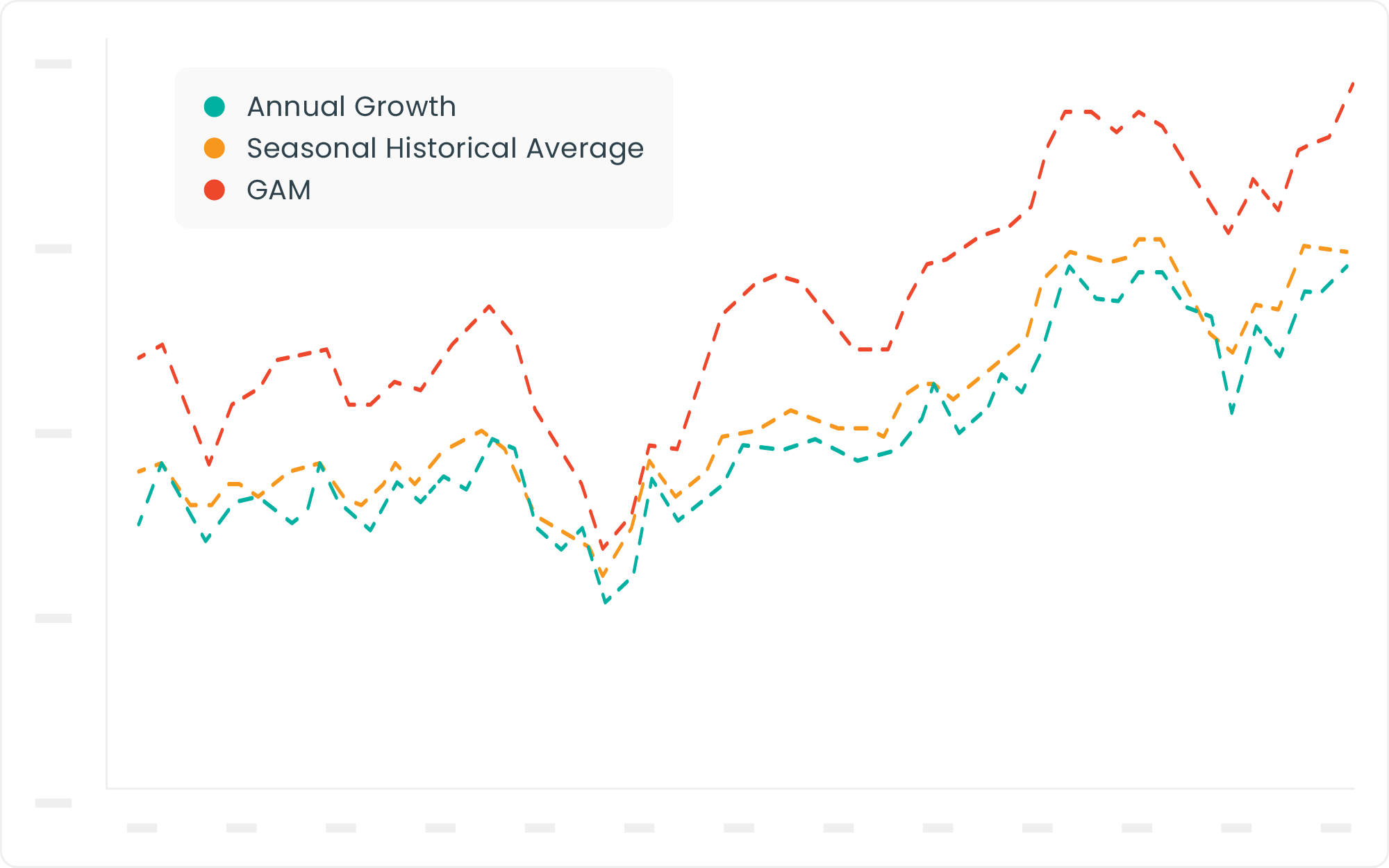

No retailer sell-through forecast? No problem. Generate accurate POS forecasts calculated down the the SKU/store level.

Understand sales deviations with automated alerts that free your analysts to focus on growing your business instead of manual reporting.

Understand relative sales and inventory performance side-by-side between retailers with the help of automatically mapped and linked product identifiers.

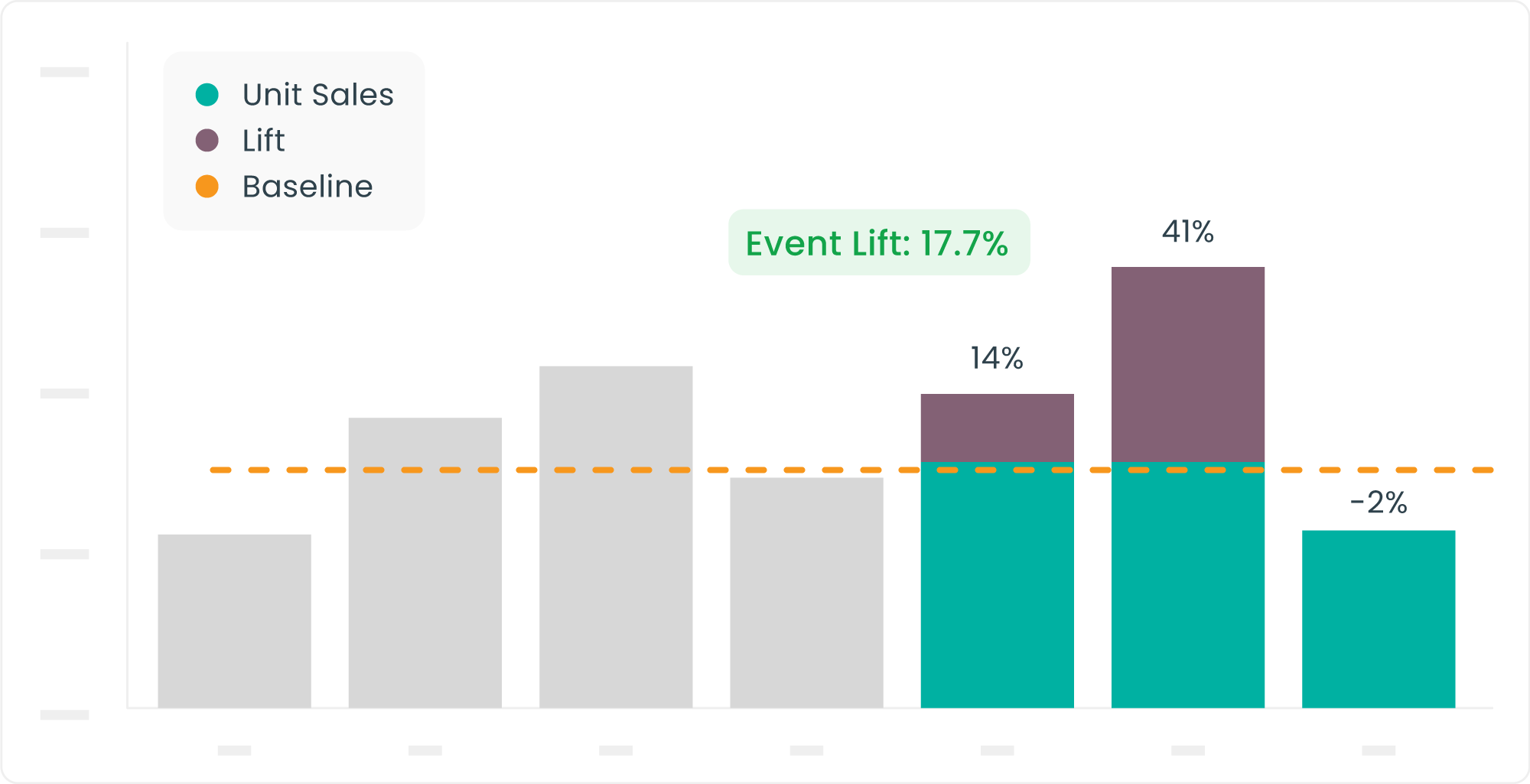

Alloy.ai brings in detailed POS data so sales and marketing teams can track performance of their promotions day one — and in real-time on an ongoing basis.

Supply Chain Visibility

Visibility Outside Your Four Walls (Finally!)

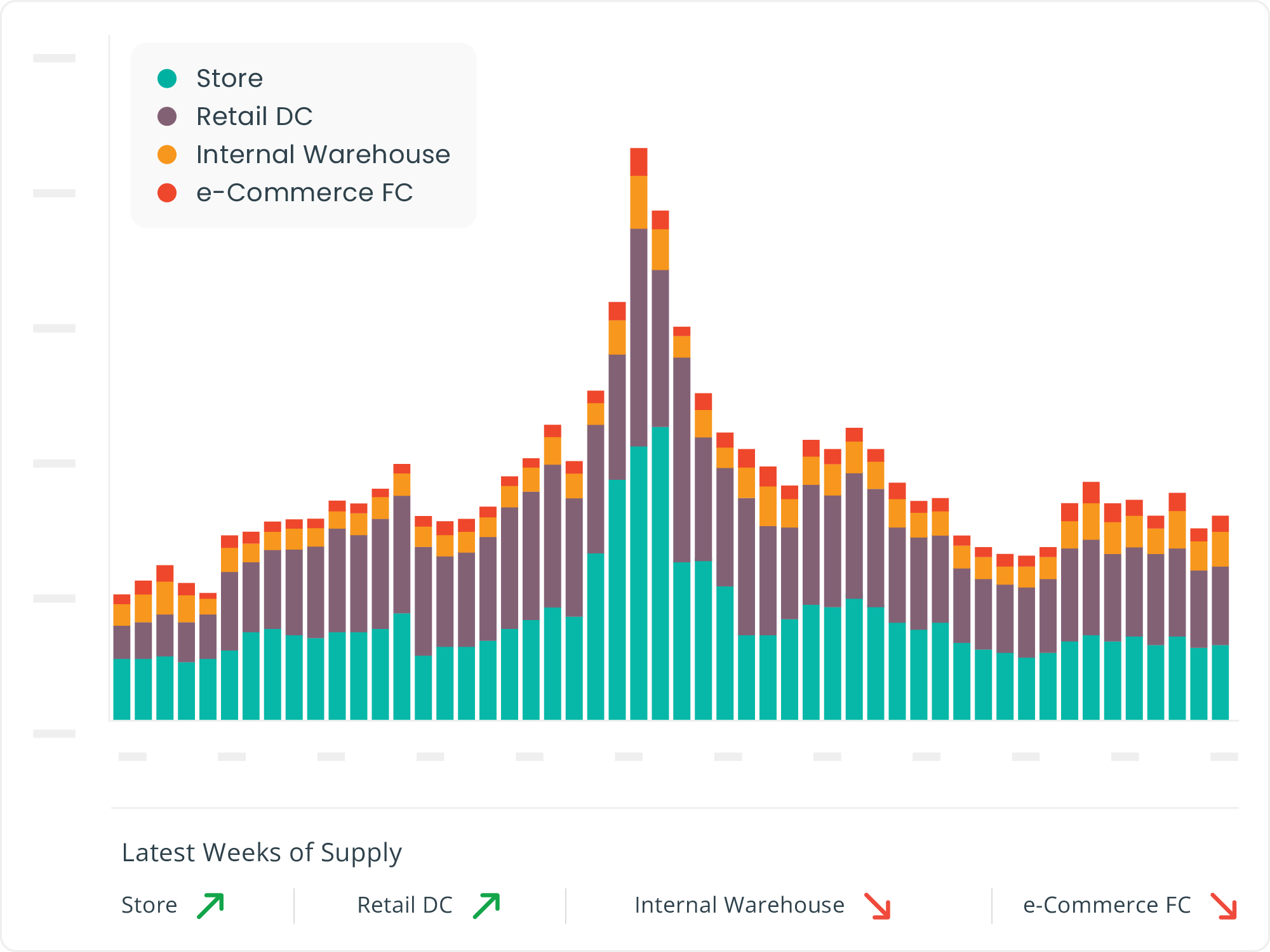

Get a full picture of your inventory across partners networks’ and your own. Alloy.ai combines retail-time data from your retail and supply chain partners with data from your ERP, so you can catch and fix supply shortages or excess inventory.

Monitor inventory levels and trends with real-time visibility across your network and your retailers’ and distributors’ networks.

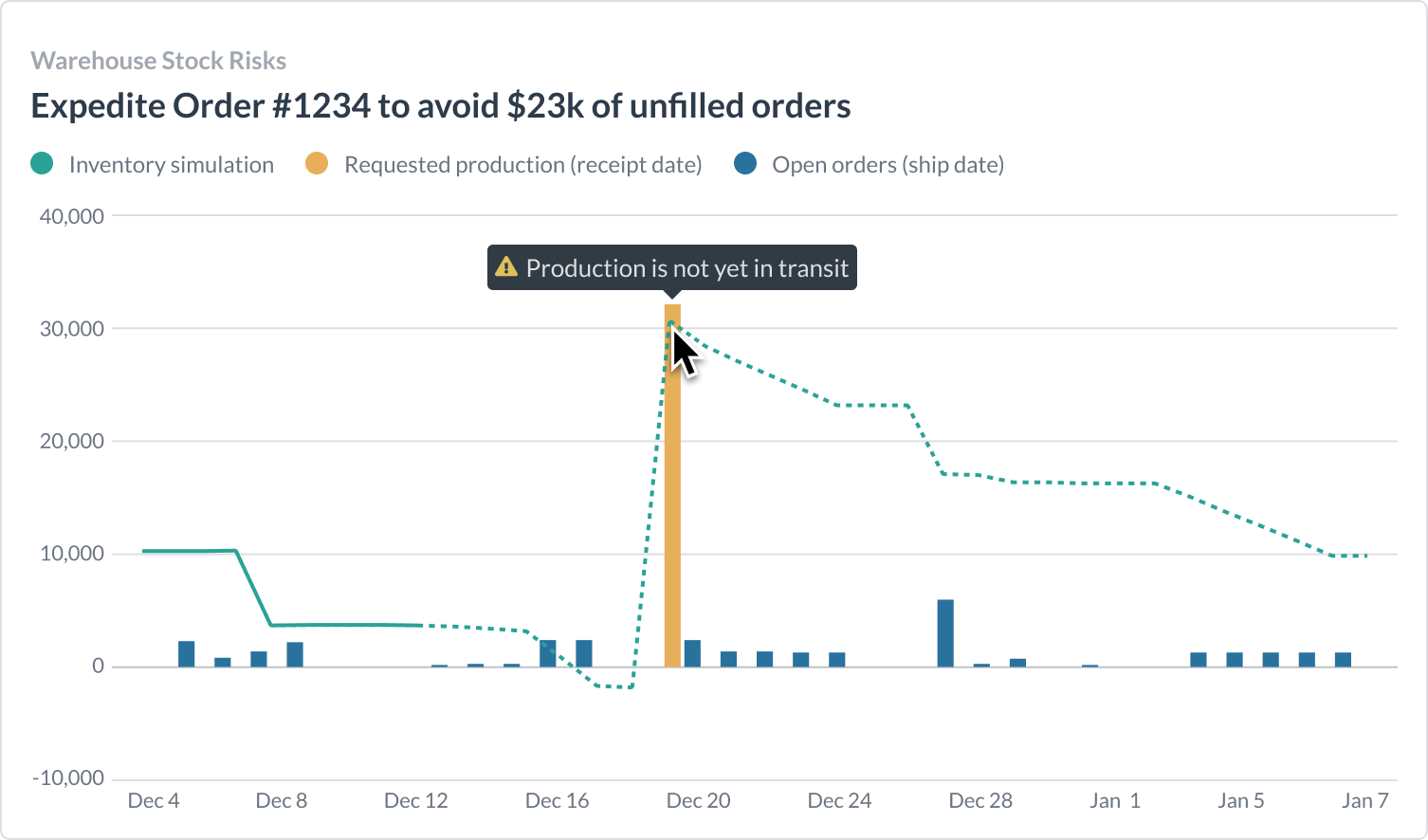

Advanced inventory and sales simulations accurately alert you to specific SKUs / locations that should be selling but aren’t so you can take corrective action.

Improve fill rates and avoid OTIF fines. Alloy.ai alerts you to your biggest stockout risks so you can take quick action.

Make data-driven allocation decisions when supply is constrained. Alloy.ai lets you allocate inventory based on where there will be the greatest dollar impact.

View complete weeks of supply so you can improve service and balance inventory levels — all without having to hunt through spreadsheets.

Artificial Intelligence Capabilities

AI Without the Mystery

Advanced machine learning forecasts, simulations and out-of-stock prevention algorithms power a set of advanced CPG-specific metrics you’ll only see in Alloy.ai.

Connect, pull and normalize data

Detect and surface problems

Extract insights from complex data with AI

Power your forecasts with ML

Simulate future scenarios

Automate replenishment recommendations

Consumer Brands Sell More With Alloy.ai

Reduction in OOS

Increased sell-in

Savings on trade spend

Increased sell-in

LEADING CONSUMER ELECTRONICS BRAND

In new sales

ROI on Alloy.ai investment

In new sales per year by identifying and reducing phantom inventory at major US retailer