- Manfred Reiche

As we recap the year, we can’t miss one of our 2018 highlights: a joint Professional Development Event with the APICS Golden Gate chapter. We welcomed members and guests to our SF office in November to discuss “Implementing a Shared Supply Chain Control Tower.”

In supply chain management, the function of a “control tower” is similar to its namesake in aviation. It provides visibility into the movement of products and “directs traffic” to optimize operations. The concept has been around for many years, but primarily focused within a company’s own four walls.

A Shared Supply Chain Control Tower Builds Trust

A control tower that is shared across trading partners, including manufacturers, suppliers, and retailers, can unlock even more value. By serving as a single source of truth and fostering trust and collaboration across enterprises, it enables all parties in the supply chain to achieve goals like reducing costs and improving customer service — beyond what any one party can achieve on their own.

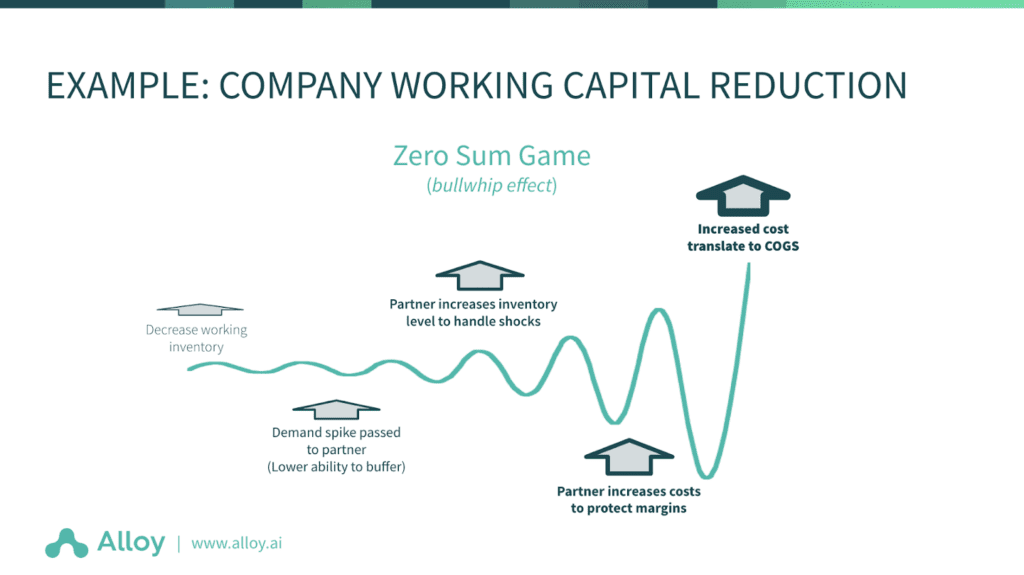

For example, consider a manufacturer that’s looking to reduce working capital and decides to decrease its working inventory. When a demand spike occurs, they don’t have sufficient safety stock to cover it. They have to quickly place a large order, passing on the demand spike to their supplier. The supplier then increases their inventory levels to handle these shocks, and subsequently increases prices to protect their margins. That increase translates to higher Cost of Goods Sold for the manufacturer, so while they may have reduced working capital, they are paying for it in another way.

Many will recognize this illustration as the bullwhip effect. The result is a zero-sum game as costs simply get shifted around and companies see limited, short-term benefits. By contrast, if manufacturers and suppliers work together, quickly passing on information when demand or supply changes occur and taking into account mutual inventory levels to form a joint response, they can both improve working capital and costs. A shared supply chain control tower can break the deadlock of companies optimizing on their own by driving collaboration, leading to more value for all partners.

Key Features of a Shared Supply Chain Control Tower

To achieve this vision, a shared supply chain control tower should include:

- End-to-end supply chain visibility

- Predictive modeling and recommendations

- Management by exception with analytics and smart alerts

- Internal/external collaboration tools

These features help overcome one of the first challenges companies come across when embarking on any visibility project: gaining partner buy-in to share the required data. The concept of a shared control tower makes data sharing a two-way street. By providing transparency into the analytics that drive recommendations for improvement, it facilitates collaboration toward common goals.

Digital supply chain capabilities also make the insights from the data actionable, so partners can see clear value from data sharing, without significant additional resource investment. Companies implementing shared supply chain control towers have realized benefits ranging from faster crisis response to elevated supplier relationships to reductions in expedited shipping costs and inventory carrying costs.

Evaluating the Benefits to Your Business

So does a shared supply chain control tower make sense for your business? Below are a few questions you can ask to help determine if it’s a good fit for your company.

- How long is my supply chain? If you already control the majority of your supply chain, you probably have good visibility into the data you need for informed decision-making. On the other hand, a longer supply chain has more opportunities for optimization and benefits more from the near-real-time data that a control tower can provide.

- How do my partners fit into my supply chain? If you’re only a small portion of your supplier’s business, they may be less receptive to a shared control tower. If optimizations in the supply chain would really move the needle for your partners, however, they’re much more likely to engage with the idea.

- Where can I start and trigger a snowball effect? If there are specific partners you can think of that would really see the benefit of sharing data, you have a clear starting point. That experience creates proof points for further integrations to grow the number of partners and the value that you get from a shared control tower.

Manfred Reiche

Manfred Reiche is Alloy.ai‘s subject matter expert on all things related to retail data and products. He spent his time at Alloy.ai being hands-on with some of our most sophisticated brands in the consumer goods industry. Prior to joining us at Alloy.ai, Manfred started his career as a technical consultant at Deloitte, focused on SAP implementations.

Retailer POS Forecast Dashboard Demo Video

Watch Alloy.ai’s POS Forecast demo: demand-sensing forecasts, forward-looking WoS, weekly backtesting, and exports to planning systems to prevent stockouts.

Collaborative Replenishment Dashboard Demo Video

Watch the Alloy.ai Collaborative Replenishment demo to see how you can surface current and chronic out-of-stocks and phantom inventory, and align with retail partners to…

Cross-Retailer Scorecard Demo – Monitoring Inventory & Sales Trends Across Retailers

Watch Alloy.ai’s Cross-Retailer Scorecard demo to compare retailer performance weekly, spot outliers fast, and drill from partner to location to SKU to act fast.

350+ Integrations for Consumer Brands

✔ POS data from 100s of partners

✔ ERP shipment and inventory data

✔ Automatically normalize data