Valvoline Transforms Customer Relationships with a Proactive Supply Chain

Valvoline, a market leader in motor oil, navigated a complex challenge—finding clarity in a multi-tier supply chain that includes third-party distributors, big-box stores, and its own service centers. Limited downstream visibility meant it was hard to know what was happening at the point-of-sale; caught off guard by unplanned orders, they often dealt with out-of-stocks and service level issues that hurt their customer and consumer relationships.

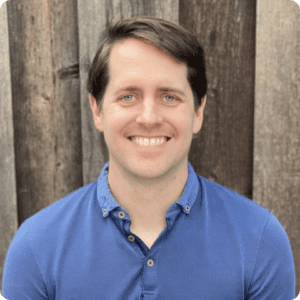

Eric Rossi, Senior Director of Supply Chain at Valvoline, shares how they drive interactive conversations with customers and distributors to avoid lost sales, OTIF fines, and unproductive inventory.

- Untangled a multi-tier network to show, in real time, what’s really happening from production & warehouses to point of sale

- Identified millions of dollars in orders at risk that, without end-to-end visibility, would’ve gone under the radar

- Now relies on predictive analytics to simulate future inventory, enabling them to get ahead of potential issues instead of putting out fires

Hear it straight from Eric — watch the full webinar below.

About the Speakers

Eric Rossi

Sr. Director of Supply Chain

Valvoline

Eric started working for Valvoline in 1997 in Operations. Since then, he has held a variety of leadership roles, including managing in several lubricant and chemical plants and warehouses, and managing Supply Chain groups responsible for Supply Chain Planning, Customer Service, Logistics, Master Data, and E-commerce.

Eric holds an MBA from Georgia State University and a Bachelor of Science in Chemistry from Clemson University.

Logan Ensign

VP Client Solutions

Alloy.ai

Logan is an expert in predictive analytics. At Alloy.ai, he leads the team that works closely with customers to help them maximize value from the platform. They are focused on ensuring fast implementation, delivering training, sharing best practices, and conducting regular business reviews.

He joined Alloy.ai from InsideSales.com, where he led the company’s highest-end service, Momentum PRIME. For customers who wanted to use predictive analytics to transform their sales operations, his team formed long-term relationships focused on optimizing sales processes and strategy, and ultimately delivering and showcasing value.

Logan’s early career was at RIC Insurance General Agency, where he worked in Corporate Strategy and Sales. He holds a degree in Biology and a minor in Economics from Stanford University.

Webinar Transcript

Introduction

Logan: Welcome, everyone, and I’m really excited to have you here! We’ve got a great conversation set for today with a supply chain leader.

Really just want to welcome Eric Rossi, who is the Senior Director of Supply Chain at Valvoline. Eric graduated from Clemson University with a degree in chemistry. He then went on to get his MBA from Georgia State University. He started working for Valvoline back in 1997 in Operations, and he’s managed several lubricant and chemical plants and warehouses. He’s also managed numerous supply chain groups at Valvoline that include supply chain planning, customer service, logistics, master data, and eCommerce.

Editorializing a bit, we’ve been working together at Alloy for the last couple of years, and he’s just a fantastic partner, thought leader, and really innovative supply chain leader. So, I’m really excited to have him! Eric, with that, you can go ahead and kick us off.

Eric: Great. Thank you, Logan. And welcome to everybody. Thank you for giving me this opportunity to have this conversation with you today. It’s an area that I am passionate about and enjoy talking about, so Logan and others will have to keep me limited to my half an hour as I go through my slides.

What I wanted to mainly talk to you about today is the journey that Valvoline has been going on with Alloy for the last couple of years. To be quite honest with you, it’s a journey that we continue to go on moving forward. It has truly been a really good partnership for these first couple of years. We see great, great things on the horizon as we start to try to fill in some of these gaps and connect some of these dots, which I listed as the presentation title here, as we move forward with Alloy.

Real quickly, I wanted to just give you a little bit of an understanding of who Valvoline is and what we’re all about. For those of you guys and gals who are our car people, you probably know us quite a bit. We are a lubricant and automotive services company. We’ve actually been around for over 150 years. The founder of Valvoline actually invented lubricants and did so, like I said, over 150 years ago, so we’ve been in the business for a while. We are a global company. We’re in more than 140 different countries around the world. We are the number three passenger car oil when it comes to the DIY market, or the do-it-yourself market. Then many of you may know our company from the Valvoline Instant Oil Changes that you see around the country, which continue to grow, and truly is our quickest and fastest growing part of our company at this point.

Like I said, we’ve been around for a long time, and amazingly, over the last couple of years, we’re still learning. We’re still getting better, and we’ve used Alloy to help us improve in several areas over the last couple of years.

I wanted to show you a little bit more about where we’re at, what our supply chain looks like. This obviously is focused more on just North America. We’ve got locations, distribution sites, and manufacturing sites all over the world, but for the point of this presentation and our relationship with Alloy, it has been, for the most part, centered in North America, so I stuck with the North America map at this point. The main reason I wanted to show you this is not to really go into the details of where we are, but what I really wanted to point out is: you see a lot of light gray space on this map, areas where we aren’t at and where we have to depend on third parties and other folks to help us in our supply chain. This is the area where Alloy has really made a big difference for us in covering our country and giving us some of that visibility we need as we move forward, and trying to get better from a supply chain perspective.

Valvoline’s Supply Chain - Before and Now

I wanted to give you an idea of what our supply chain looks like today, and actually what it looked like a couple of years ago before we started this relationship with Alloy. Then I’ll start to talk about some of the problems that Alloy has been able to help us solve. I’ll show you a much more complicated supply chain that Alloy has helped us adjust to over the years.

For the most part, you can see that what’s represented here is that the factories here are manufacturing sites, and the pallets of cases that you see there are distribution sites. For many, many years, going back a long time – and I’ve been with the company for a long time – this is the area that we focused on. If we were okay with our manufacturing, if we were okay at our distribution sites, making sure we have the right inventories, the right safety stocks, that we were scheduling correctly or planning correctly, we felt like we were doing a pretty good job. For the most part, as long as we were servicing those retail distribution sites and those installer distribution sites, we were actually feeling like we were in pretty good shape.

Quite honestly, a very simplistic point of view and a view that actually hurt us quite a bit as we moved forward. As our customers started to demand more of us, we started to try to take more ownership of our supply chain. As we moved forward, it became more and more important for us to start to understand some of that downstream stuff that we didn’t have visibility into and we didn’t have access to, that Alloy has helped us do over the last couple of years.

While I’m on this slide, I also wanted to explain something that I think is important for the rest of the presentation. We primarily have two supply chains in North America. One is represented by the red and blue truck there, and the other is represented by the black truck that you see there. We basically service two very distinct supply chains that have very different needs.

One is what I’ll call our retail distribution. Our DIY network, where we’re servicing large retail customers, we’re servicing their distribution centers, and those distribution centers are servicing the thousands and thousands of retail stores you see around the country. Typically, what we’re sending through that particular supply chain are case goods. If you think of a bottle on the shelf or a case on the shelf, that’s what’s typically flowing through that supply chain.

Then, when you jump over more into the installer supply chain, this is where we’re actually servicing the folks who are putting oil into your car. The garages, our Valvoline Instant Oil Change shops, car dealerships, and even mom-and-pop type operations where you’re getting your oil change. That is that particular supply chain. Currently, both of those are about 50/50 in our North American business. The installer piece of it is growing much faster as people are depending more and more on others to change their oil, but both are very important to our company. Making sure it’s integrated and we have complete visibility throughout the supply chain.

This one is meant to show what we’re doing from more of a modern perspective. As you can see here, as we start to grow, as our supply chain starts to get more and more complicated, we have to start understanding further downstream in our supply chain – both from the retail supply chain and the installer supply chain. We started to add layers to our supply chain, where it became more and more important for us to gain that visibility.

Still, before we started the relationship with Alloy, we had visibility into a very small section of our supply chain. But what was becoming more and more apparent to us is that we needed to grow that visibility. That green area that you see is only focused on our sites, on our distribution centers, and is needed to grow both upstream and downstream to include many more layers of our supply chain, so that we can start to gain that visibility. Start to become more proactive in dealing with those layers further down in the supply chain.

Alloy has helped to create many of the tools that we use today to gain that visibility, to become more proactive as we go further down our supply chain. That’s primarily what I want to focus on in the rest of the presentation, demonstrating to you how Alloy and we are partnering together have started to expand some of that green area much further beyond what we see today in this slide.

Problem Statement

The four areas that I’m going to touch on: the two dark blue areas are primarily with our retail supply chain, and the light blue areas are primarily with our installer supply chain. Both are extremely important and very vital to our supply chain to continue to service those areas.

Number one, we needed to become much more proactive in our retail supply chain. As we started to get more involved and started to understand a little bit more around the POS data that we were starting to get back from some of our retail accounts, we needed to be able to implement and integrate that data into our supply chain, so that we could start to take advantage upstream in our supply chain and understand what was going on two and three layers downstream. As we started to get that data, we needed a place to be able to digest that data, to be able to translate that data, and to be able to use it further up in our supply chain, so that we could start to take advantage weeks ahead of time – before that POS data made its way through the supply chain. Alloy has helped us do that.

Secondly, it was becoming more and more important for us to be able to talk to our customers, to be able to have those interactive conversations with our customers, so we became more of a partner with them. Today, when we go out and talk to our customers, it’s a very interactive conversation because we have access to this data. We actually try to help them within their own supply chains to get better, to get more efficient, to get more cost-effective. Because Alloy has been able to provide that data for us in a digestible form – so that we can take that data and work with it, massage it, make it work for us – we can have some more of those conversations further downstream to help us work with our customers.

Flipping over to more of the installer supply chain, the big thing that we were lacking right there is visibility. If you remember back a few slides, in that picture that had all that light gray area around the United States, we have to depend on a lot of third parties to help us service those areas and help us service those garages, our Valvoline Instant Oil Changes, the car dealerships. We didn’t have visibility into that data to understand what was going on further down in the supply chain. With the help of Alloy, we are starting to go down that journey now, to where we’re starting to connect some of those dots. We’re gaining more and more visibility into that gray space so that we have a better understanding of what’s happening further downstream.

Then the fourth piece there, what I wanted to talk about is how Alloy is taking all of this, and they are truly starting to allow us to be what I call a strategic weapon to our sales and marketing team. We are actually starting to use some of this supply chain capability that we’re gaining from Alloy to be able to market that to our customers to say, “Hey, look what we can do for you. Look how we can help you, look what we can provide you, what visibility we can provide you, what data we can provide you, what metrics we can provide you coming out of Alloy.” Because we’re able to digest some of that data.

I’m gonna take a second here to make sure you are still awake on me. We wanted to have a poll for you. We wanted to ask, what are your top supply chain priorities? You heard me talk a little bit from a Valvoline perspective: visibility, integration with our customers, and being proactive. All of those types of things are helping us to improve some of these things, like fill rates, like relationships with our customers, like our forecast accuracy, even. So we wanted to understand a little bit more from your perspective as well. What are you seeing? What are your priorities in your supply chain? We’re hoping that we can understand a little bit more about what you’re seeing out there in your supply chains.

All right. I’m seeing the votes come back. Forecast accuracy is dominating right now. Customer relationships are pretty high as well. Going with those two things in particular, the forecast accuracy and the strengthening of the relationships, both of those are huge issues for Valvoline as well. Alloy in both of those cases has helped us tremendously. I’m gonna talk a little bit more and show you some examples of the relationship strengthening in a couple of slides. I don’t have a whole lot on forecast accuracy in here, but if you wanted to have some other conversations with me outside of this webinar, I’d be happy to do that. We are starting to take some of that POS data to help us be a better forecaster of our customers as well. I think that is something we can touch on as we start to go through the presentation a little bit more as well.

Becoming More Proactive

Once again, splitting this up between our retail supply chain and our installer supply chain. To reflect back, this is our retail supply chain – shipping to their DCs and then obviously, those DCs shipping to the stores. As you remember, the green area before was simply just our manufacturing, just our DCs. Now we have visibility throughout that retail supply chain. This is where I’m gonna show you some of the examples of what Alloy is doing for us to give us that visibility throughout the supply chain.

This is one of my favorite pieces here. I’ve talked a little bit about how getting this data in helps us to be more prepared and more proactive. This screen right here is something that I pull up every single day when I come in to get an overall understanding of what things look like. To give you an idea of what this is all about, these are some of our key accounts. These are some of our key retail accounts that we have, which we service from Valvoline. The graph on the far right is POS data. This is what’s going out of our retail stores, that we’re shipping out on a day-to-day basis as customers are coming in. The middle graph is what we have available at those DCs, so our retailer DCs. The graph on the left-hand side is exactly what’s coming out of our DCs.

I now have visibility to three layers of the supply chain instantaneously, coming in every morning. I can start to be very, very proactive and prepared further up my supply chain as I’m seeing some of this data change. From the very start, from the POS data, and then slowly progressing to the DC data, and then obviously getting back to what’s actually going to be put on order for us. Those folks who are interested in the forecastability, this is where that’s starting to feed in. As we start to understand those layers of our supply chain and understand what that POS data is able to provide us, we can start to be more proactive as we move from right to left on this. We can start to understand what our customers are going to be ordering.

For instance, if you look at the graph on the right and in the middle, it is very smooth. But look what the order patterns from our customers are looking like on the left-hand side, very up and down. As we start to gain a better understanding and have those conversations with those customers, we could do a better job of smoothing out that inventory and smoothing out those orders so that we are better prepared to understand what our customers are gonna need moving forward.

Secondly, this chart here or this dashboard here is simply just taking what I just showed you at a very high level and breaking it down even further. There are people within my organization who are actually taking it down even further to this level of detail. They’re actually able to look at those three graphs I showed you before, and they can actually look at it at a store level, at a DC level, by product, and fully understand what’s going on at every layer within our supply chain.

The wonderful part about this is that they can do it by managing by exception. We have thousands of products that we sell across hundreds of DCs, across thousands of stores. Alloy allows us to understand where some of those issues are at a SKU level, at a DC level, and at a store level, and we can start to be very proactive within our supply chain. Understanding where those problems are in this graph helps us to do that.

Strengthening Customer Relationships

Moving on, I talked a little bit about building those relationships, understanding those relationships, and being able to have some of those integrated and interactive supply chain conversations with our customers.

We use this graph in this dashboard that Alloy helped us create to have those conversations with our customers. We are actually able to have those conversations and literally talk to them about their store-level inventory, about their DC-level inventory. Understanding where they keep different inventory, do they need to keep more store inventory, or more DC inventory?

We can actually have those conversations with them and talk to them about areas where we believe they can actually save some money. In many cases, it’s not necessarily them being out of product or being too low on product; they may have too much product. We can have those conversations because of that information and because of that data that we have in Alloy, and we can discuss those with them. I’m telling you, those conversations really add to the relationship and help the relationship tremendously.

Finally, this is yet another dashboard to help with those conversations. I had talked about that ratio of DC inventory to store inventory. We often use this graph to help show trends of what we’re seeing and how that inventory is shifting, particularly during promotional times. Our business, at the retail level at least, is very promotionally driven. Therefore, that ratio of inventory sometimes needs to shift from the DC to the store as those promotions are happening. As those promotions are going on, we can react much faster and more easily. Have those conversations and understand where we need to shift inventory because of tools like you’re seeing on the screen right now.

Time for another poll. Wanted to understand a little bit more about the retail store POS data and how it impacts your daily decision-making. So if you would, please vote and help us to understand a little bit better around how that works in your organizations.

I would say as far as a journey within Valvoline, I think over the last two years, I think we’ve gone from rarely to most of the time. Literally, we are using POS data more and more because of the relationship with Alloy. Because they are making it so easy for us to digest the data.

A lot of people on this call are using it a lot of the time, or at least most of the time, which is great news. Very much like us, and it seems to be the evolution within our supply chain that we’re using that more and more often as we move forward.

Helping 3rd Party Distributors

Shifting over from retail now to the installer, if you remember, what we’re trying to do is gain more visibility to our supply chain. Particularly within our installer supply chain, a lot of blind spots. A lot of areas where we didn’t really know what was going on from an inventory standpoint, a forecasting standpoint, and even a service standpoint, because of the lack of data that we had. I wanted to make sure everyone understood how important this is to us, to understand the layers within that installer supply chain, and us gaining better and better visibility to that.

I talked a little bit about how we use a lot of third-party distributors to help us service those last-mile customers, those garages, those VIOCs, those dealerships that we work with. This is a dashboard that Alloy helped us to create that literally takes that point of sale data that we’re able to get at a store level or an installer level, and literally takes it back throughout our supply chain. This particular dashboard here is the one that we usually use to have those discussions with our third-party distributor network. This gives us an idea of whether they are keeping the right inventory. Are they keeping the right safety stocks? Are they servicing the customers like we need them to? Alloy helps us, once again, to do this on a very quick and easy basis, so that we can have those discussions with the distributors that are listed here. We could start to target some of those areas -whether they be at a store level, a SKU level, wherever they may be – this helps us to do it in a very digestible and easy way.

Lastly, in kind of a summarizing thing. I think what we’re trying to do here is gain visibility throughout our supply chain so that we understand the overall health of our supply chain. I think we have done a good job of getting to that point. What we’re heading for now is that we are actually trying to create those ways that we can now become that strategic weapon for our marketing and our sales teams. When they work with customers, they aim to understand what we can do from a supply chain perspective to add that extra layer of credibility, to add that extra layer of enhancement that really creates that stickiness with our customers.

This slide references yet another dashboard that Alloy created for us. We understand, if you go from left to right: what’s going on in our production facilities, what’s going on at our warehouses, what’s going on with our distribution, whether that be retail or our installer, and then the final store POS data.

We’re getting to the point now where we’re getting so good at it that we’re actually taking it to the next step with Alloy, and we’re actually managing the inventory. We’re doing that within Alloy. We are using that as an extra service to our customers, particularly on the installer side. We’re creating ways that we can actually manage the inventory ourselves because we have that visibility of data. Once again, creating some of those strategic weapons to help our sales and marketing team and to help with that relationship with our customers.

I think I used every drop of my half an hour, and I’m gonna turn it back over to Logan.

Alloy Overview

Logan: Thank you so much, Eric.

I know Eric’s presentation gave this group a lot of context on the sort of work that Alloy does, but we did want to just take a minute or two to take a step back and talk a little bit more about Alloy.

At its core, Alloy was purpose-built to be the central nervous system of the end-to-end supply chain. We recognize that supply chains have a lot of data available to them, but typically, this relevant data lives in a lot of different systems. This makes it hard to make the right data-driven decision, but it makes it even harder to make those decisions quickly. It’s always been important to be data-driven and responsive in supply chains, but what we’ve noticed recently is that it’s become even more important as we navigate through a pandemic. Consumer behavior is even less predictable now than it’s been in the past. So it’s super critical to be able to track, in near real-time, what’s going on at the point-of-sale and how that impacts the rest of your supply chain.

Where Alloy fits in here, we’re a data platform that is built with consumer goods companies in mind. We’ve got pre-built data integrations with retailers, with distributors, with ERPs, forecasting, and demand planning solutions, and we’re able to pull data from all of these sources automatically into our platform. Then a key component of our tool is that we are able to harmonize all of this really important data together. Things like unit of measure, product identifiers, fiscal calendars, distribution networks, and forecasts. It’s gonna be really tricky to stitch together, and it all can be mapped together in Alloy. This way, supply chain teams, your sales teams, finance teams, and your operations teams can look at the same data. You’re all in a single source of truth, but you have that flexibility and ability to look at it in your own language for your own sorts of applications and use cases.

Once all that data is coming in as near real-time as possible, once it’s harmonized in the data platform, you unlock a whole suite of applications depending on what you’re trying to accomplish. Sales teams can get what they need out of the data; demand planning, forecasting teams, supply chain teams, and IT teams that can all leverage this data, just in different ways.

Today, we unpacked a lot of functionality in our Alloy for Supply Chain set of use cases around inventory simulations and being able to quickly respond, get visibility into point-of-sale, and also understand how that impacts distributors, distribution centers, and production. But we have other sorts of use cases and applications, depending on which part of the business is looking to leverage Alloy. There’s a ton of value just in having all that data together for these different functions, but we also find that, as we work with our customers, once you’ve got that Alloy Data Platform in place, now you’ve got a single source of truth where you can collaborate on issues. Because typically when there are disruptions in the supply chain or analyses that need to be done, it’s quite cross-functional. Being able to kind of break down those barriers, not just from a data perspective, but break down those barriers from a team and a process perspective, so as an organization, you can all work together cross-functionally on collaborating on those issues.

I’m really grateful for Eric walking us through the journey we’ve gone through together, and we’re continuing to go on. If folks have more questions specifically about Alloy, you can feel free to reach out to Cindy on the call here, or me. We’ve also got a lot more content and details on our website, alloy.ai.

Q&A

First question came in, “How did you involve Valvoline sales and/or marketing teams in this change with Alloy?”

I can tell you that sales and marketing have been involved since day one. In fact, though this presentation was very supply chain oriented and very supply chain directed, I could have easily done another presentation around how sales and marketing are using this tool. They are very active in this, a very similar type of stuff. It’s giving them that visibility to be proactive, to have those conversations with the customer. Very good at monitoring promotions, monitoring stockouts, and being able to have those types of conversations.

Alloy and us get together every couple of weeks and talk about the users and talk about who’s using the system and that sort of thing. There are just as many sales and marketing people in our organization today as supply chain people who are using Alloy. It’s basically a 50/50 split. All those dashboards that I just showed you that are more supply chain oriented in Alloy, sales, and marketing have their own. They’re different, but once again, they’re all keen on that same data, that central hub data that we’ve got in Alloy.

The great part about it is that it not only helps with the relationships and the integration and the conversations with their customers, but it also helps with our internal conversation. When we’re talking about what we’re going to be doing next month, in 3 months, in 10 months from now, we’re using Alloy to have those conversations internally with both sales and marketing.

One of the questions was, “Did Alloy help set up the data connectivity?” I chose this question because I wanted to emphasize this question. This was a big, big deal for me. I don’t know how the rest of your IT organizations are out there, ours is very, very… It’s at capacity, let’s put it that way. They do a great job for us, and I can’t thank our IT organization enough for what they do. At the same time, the beauty of the Alloy project is that the involvement from IT has been minimal. Alloy, as far as setting up the data connectivity, it literally is, “hey Alloy, we want you to go set up this data with this customer.” A few weeks later, we come back and “bam!” there it is.

I don’t want to paint the picture that it’s that easy. But at the same time, I will say if I had to create three or four talking points around how great this has been, it’s been the speed at which Alloy works, and also the ability for us to have minimal responsibility when it comes to that connectivity. It’s more of, what do we want? How do we want to see the data? How do we want to digest the data? All the complicated behind-the-scenes stuff that I don’t know a whole lot about, Alloy handles for me. That’s been a really nice feature of the relationship with Alloy.

Another question is, “How do you handle customers that don’t provide POS data?” I’ll say a couple of things there. We do have customers for whom we don’t have POS data at this time.

Point number one, I will say that our customers, because of how easy Alloy makes it, customers that we had before that had been very resistant to providing us data have become fans of providing us data. We’ve seen a lot of cases where customers, because it has become so easy and because they can see the early dividends of providing that data to us, have become advocates of providing that data.

But we still have those customers that don’t. We use different techniques behind the scenes within the supply chain to be able to actively predict what those customers that are not going to be providing us data are gonna do. Very often, we use similar customers within the supply chain to do that predictive analysis. If we’ve got a customer that is providing the data, that is providing the data actively and we got a good relationship there, and it’s a similar type customer when it comes to size and ordering patterns and that sort of thing, we will typically mimic the data in our system so that we can get an understanding and be able to provide the information upstream as to what those customers are going to do. At the very least, what we will sometimes do is, we’ll have to use old-fashioned type supply chain techniques. Go more upstream, where we do have the data more readily available within our own systems, and try to, in some form or fashion, extrapolate that data from a forecast perspective. Not as easy, not done as well as the POS data, but still, we’re able to provide that and move forward.

Let’s see here… “Were the connections to distributors’ data automated with API type technology or the use of portals?” All of the above. We have a plethora of ways in which we’re absorbing data. Our more sophisticated customers are using API type technology to provide that data, but we also have customers that are able to provide either through a portal or even a simple email, a flat file. We’re getting data in a multitude of different ways. In many cases, Alloy makes those adjustments and can digest that data in a multitude of different ways.

One of the other things, too, is that it’s not only the methodology in which that data is coming in, but the condition of that data when it does come in. As you can imagine, in some cases, that data requires a whole lot of translation to be done. Alloy, once again, is truly a data expert. They’re able to actually go in and interpret a lot of that data, work directly with that customer to understand how we can digest that data, even though the terminology may be different, the fields may be different, the way the data is coming in may be different, and even the timing of the data may be different. I think because of what Alloy does and as they serve as that in between, between us and the customer, they help us to translate that data from a customer’s systems to our systems. Serve as that conduit between the two systems to help us digest that data.

Last question I have on here, “Did you justify the cost of the project based on inventory reduction and efficiency?” Partly. There’s no doubt that was part of the justification. A lot of the other pieces of the justification were the ability to gain that visibility, which obviously leads to inventory reduction, but at the same time, we’re also able to justify the cost a lot based on that whole relationship thing in working with the customers. I think the big thing as we move forward, as well, and we always had this in mind from the start, is the ability to start managing our customers’ inventory. The justification for that was pretty easy. As you can imagine, when you have complete control of your supply chain, including what the customer is actually ordering, the justification around that was quite easy and pretty easy to get by our leadership.

Logan: Thank you so much, Eric. I think you’ve got a great sense of timing here. It’s 45 exactly. Really appreciate you walking us through that.

Thank you, everyone, for attending. Like I said, we can continue the conversation. Don’t hesitate to connect with me or other folks at Alloy, but otherwise, just really appreciate people giving us some of their time today. For those of you impacted by all of the weather, stay safe and enjoy the rest of your Thursday.

Beware the Gap | Infographic on Supply Chain Survey Results

What consumer goods supply chain professionals said about top priorities, challenges responding to consumer demand changes and inventory management gaps

Beware the Gap | Infographic on Supply Chain Firefighting

Supply chain firefighting may be an accepted fact, but how has it changed in recent years? We examine trends in contributing factors, how companies respond…

Purpose-Built for Consumer Goods Brands

.png)