Talking better product launch and allocation decisions with Ferrero USA

The global confectioner mitigates waste, improves service levels and controls costs by connecting digital supply chain visibility with POS analytics.

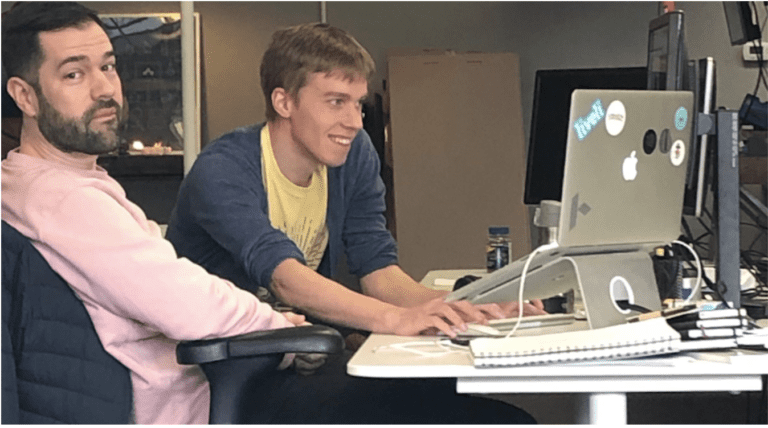

Keep readingLasse Holmstedt is Head of Engineering, based in Alloy’s Berlin office. Prior to Alloy, he worked for 7 years at Nokia on devices like Nokia X, the company’s first AOSP-based device. He was also the dev lead for Nokia Maps for Android and a developer on Qt Creator, a C++ IDE.

I’ve always been a product-driven engineer. Ten years ago, when building apps as personal projects, I focused on shipping complete, polished apps. I learned in a very concrete sense how much of a difference it makes to throw something together vs. spend the extra effort to make sure the user experience really works!

In most of the teams I’ve worked on, I’ve been close to the product, and it’s what I have enjoyed the most. That’s also what got me hooked on Alloy. Although the domain is very different from what I worked on before, the value proposition was clear from the start when I met Roby, one of the co-founders of Alloy.

As a bit of personal motivation, I had always wanted the challenge of jumping into an early-stage startup, so Alloy checked a lot of boxes for me.

I split my time between recruiting, engineering, and product work. We’re hiring across three different offices, and I really enjoy talking about the value of Alloy and learning more about candidates!

In terms of engineering, I’ve worked on all things from continuous integration (CI) to backend and shell scripts, but my real passion is with the front-end. Within Alloy, there is such a vast amount of data that you need to distill into high-level insights for the user; it’s an interesting challenge to build a platform that gives you those key takeaways, but also lets you zoom into the details when needed.

I work closely with our Head of Design, to define what the platform should look like and how we drive the most value for the end user, whether they’re a sales analyst, a category planner, or an executive. It’s very rewarding how quickly we can iterate and work toward a minimal, shippable product, which is a night and day difference from my former career!

I have a couple favorites, for different reasons. The first one is the initial full rewrite of the UI that I did with Craig in 2016. It was very exciting for me because I had just started at Alloy, got to learn technologies that were new to me, and work with a talented designer who also knows how to make things look great in code. I think it was the best possible start because you could see the impact of your own work in such a different way than what I’d experienced in my past jobs.

Another very exciting project is a recent one from the past few months, demand planning. It’s a new module in Alloy we’re building that facilitates the demand planners’ job. We pull all of your key planning numbers together in a single platform, from forecasts to promotional events to available inventory, and produce order and inventory level recommendations. It’s been very gratifying to work on it together with our customers.

The best part of this project has been the team collaboration. Everyone has done a tremendous job, and as a result, I’ve seen the product go from initial user calls and paper prototypes to everything clicking together and customers on-boarded just five months later. It would not have been possible without everyone, from Sales to Client Solutions to Engineering, all doing their part and pulling together.

Initially, it was definitely a big transition for me to start thinking in functional programming terms because I had done object-oriented programming (OOP) for years. It’s easy to learn new languages, but orienting your thinking to a more functional approach was a much bigger shift.

After that, the biggest challenge has been figuring out the right thing to build. There’s so many different directions you could go in, and effectively prioritizing on a personal level, as well as on a team and company level, is just super hard! When you get it right, it’s very satisfying, but as with any company out there, we’ve had a few mis-steps and built features that users did not end up leveraging. We’ve learned from each one, and I’m very happy we’re getting better at it, though it really takes the whole team to focus on what matters.

I think as an engineer, it’s important to see programming languages, libraries, and whatnot just as a means to an end, and be open to learning new ones. The same thing goes for agile methodologies, waterfall, etc. − none of it matters if you’re not building the right thing to begin with. Focus on trying to understand the user need that you’re solving for, and how you can solve it in a minimal yet maintainable way.

Computer games. I always wanted to make one myself, so I set off on that journey when I was 13. My first programming language was Visual Basic − I know, not a popular choice, but at the time, DirectX 7 libraries had just shipped to it, so it was easy to start off with graphics programming.

So I tried to build a top-down shooter game without knowing the first thing about how to make games. I never finished the game, but after that, I started to enjoy game development more than the games themselves.

I really enjoy how transparent everything is at Alloy. Most of the communication is in public channels like GitHub, Slack, Google Docs, Clubhouse (ticketing), or Guru (wiki). We can see what customer contracts look like, understand our status with customers in general, and even jump into customer calls to get a better feel of how they are using the product. Every engineer is making small, daily decisions that shape the product, so transparent and asynchronous communication is also key for us to be able to make all those calls in the code we touch.

Another aspect of the Alloy culture that really resonates with me is how others are willing to step in to help, even when they don’t have to. It ranges from engineers grooming user stories on their own, to updating libraries proactively, to helping out with setting up office furniture and stepping in when someone gets sick. When a team member is stressed or under pressure to deliver, we all work together to help. And when we succeed, it really makes you proud to have reached those goals together.

Cycle! I try to work out frequently, and while I don’t have the legs to stay apace of the big guys on flat roads, I can hold my ground pretty well on hills and mountains. Berlin is unfortunately very flat, but you can always go up and down the same hill for as long as you’d like − that’s the kind of crazy I am. I’ve also done “silly” things like the Hells 500 challenge, where you cycle 500km / 10,000m vertical ascent (the height of Mount Everest) in under 36 hours. I don’t necessarily recommend that to anyone, but I’d probably do it again.

The global confectioner mitigates waste, improves service levels and controls costs by connecting digital supply chain visibility with POS analytics.

Keep readingHow to take an iterative approach to digital supply chain transformation with real-time alerts that motivate teams to collaborate on issue resolution

Keep readingUnderstand how gaps between systems, teams and processes are keeping you constantly firefighting and hurting your supply chain resilience

Keep reading