Alloy.ai Data Platform

Pull & Normalize POS & Supply Chain Data

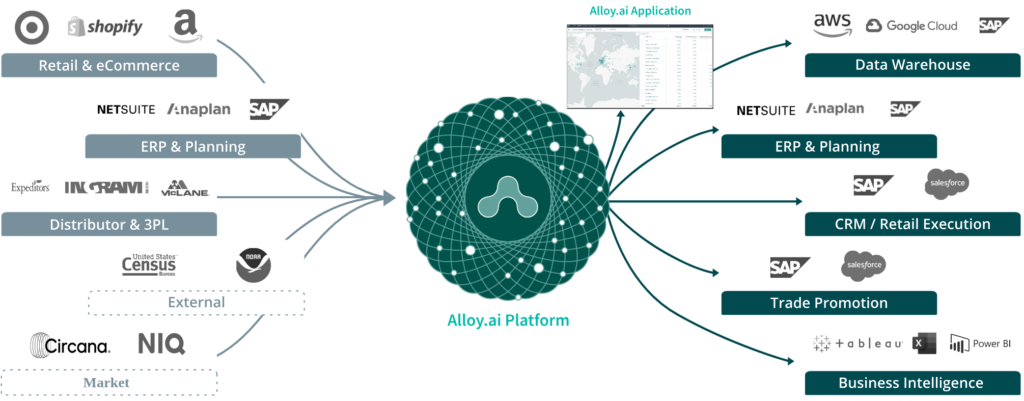

Ingest data from 100s of sources

+ 100s more

✔ POS data from 100s of partners

✔ Automatically normalize data

✔ Integration w/ data warehouses

✔ ERP shipment & inventory data

✔ AI-powered predictive metrics

✔ Integration w/ leading BI apps

An enterprise-scale data platform

(minus the enterprise complexity)

Alloy.ai is much more than a retail data platform. We combine external data (retail, ecommerce, distributor) with internal data (ERP, transactional, promotions) for better insights across sales & inventory. And we manage and update the ETL pipeline — letting your team focus on the more critical parts of your business.

Easily move data to power your consumer brand

Granular data collection

100s of pre-built connectors use techniques like RPA to continuously ingest POS and inventory data at the most detailed levels.

Integrate from anywhere

Partner portals, EDI, spreadsheets, email forwarding, APIs and more — Alloy.ai has solved the challenge of pulling the data CPGs need.

Zoom in / Zoom out

Whether you need the latest daily sales data at item-location granularity or exec-level , cross-retailer insights, find it in Alloy.ai with a few click.

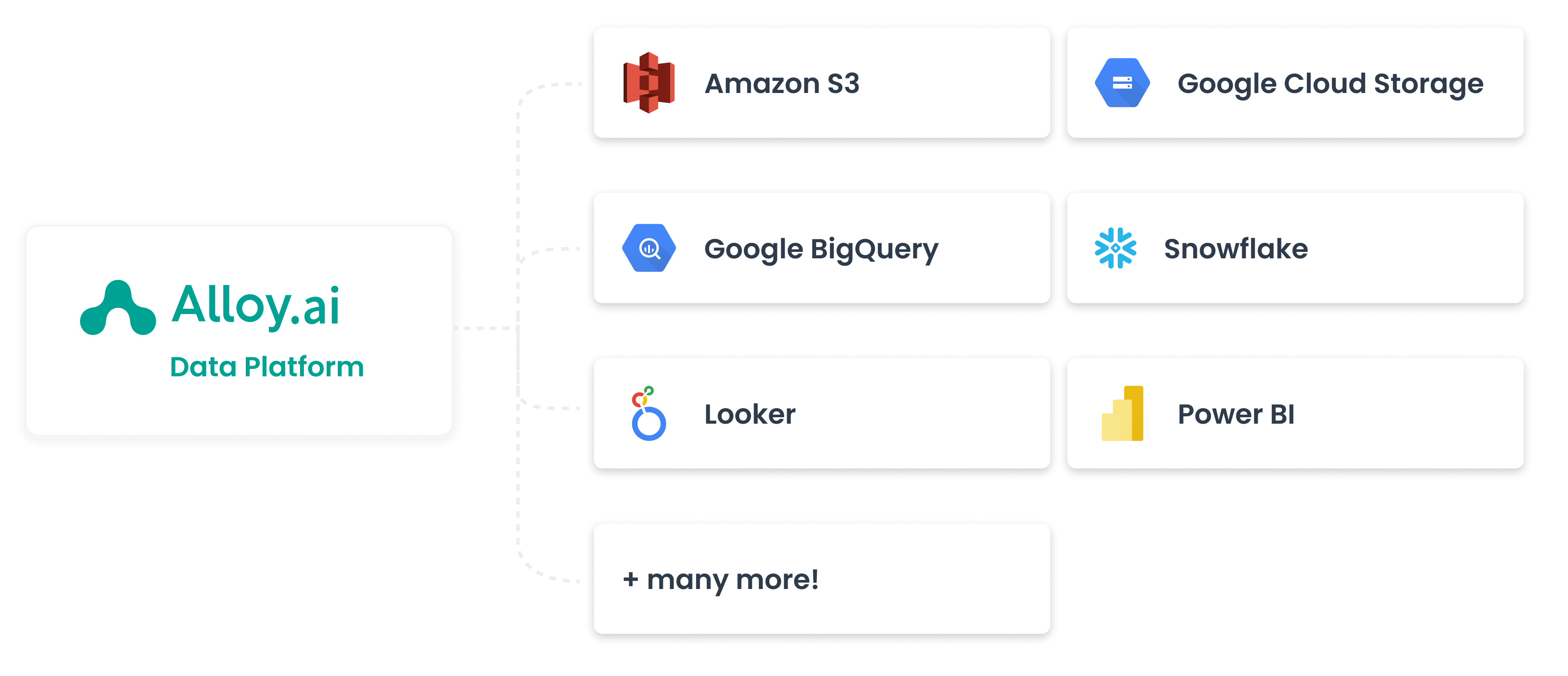

Create a single source of truth

Alloy.ai directly integrates with BigQuery, Snowflake, and other data warehouses, letting you centralize data where you want it.

Always up-to-date

The instant new data is available, your data share will update with all of your partner data — fully normalized, at any scale.

Visibility at scale

Selling 100k+ SKUs across 100 different retailers and distributors? No problem! Alloy.ai easily scales to handle complex, global CPGs.

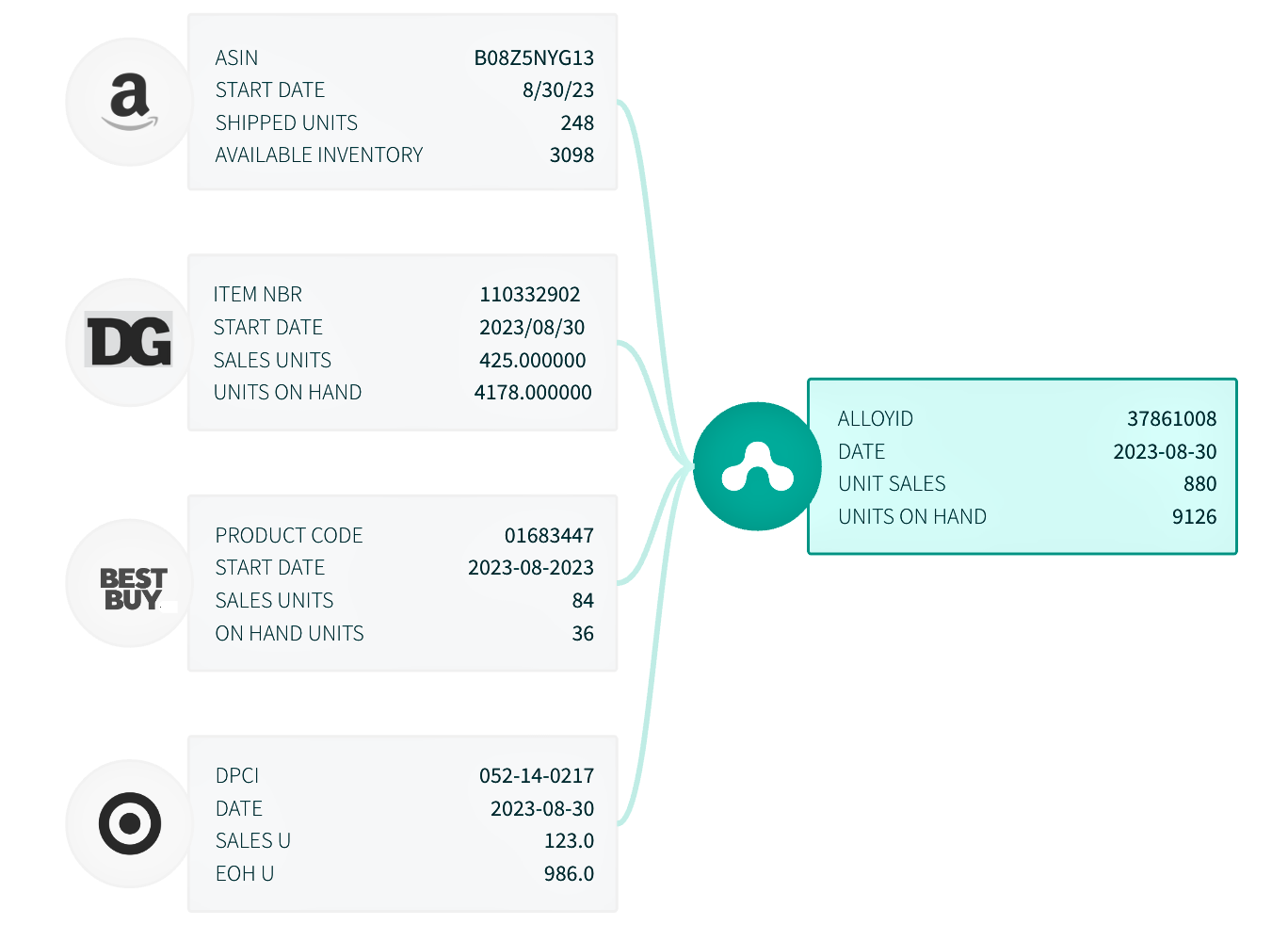

The most powerful normalization engine for consumer brand data

The normalization layer of the Alloy.ai data platform automatically translates disparate data sources and types into a single, unified representation of your business. Alloy.ai automatically ingests POS data in the retailer’s taxonomy with no effort from you. When you bring in your own product master, Alloy.ai automatically maps retailer products to your company’s taxonomy.

Alloy.ai automatically normalizes your data by:

Location ⬥ Product ID ⬥ Units of Measurement ⬥ Time

A unified graph of your supply chain

Alloy.ai automatically builds a supply chain graph as data is ingested, making graph connections visible to you.

This means Alloy.ai understand s available supply at each location and that location’s points of connection — for more accurate replenishment recommendations, forecasting models and more.

Bring POS data into your favorite applications and solutions

Alloy.ai lets you easily integrate normalized, real-time sales and inventory data — by location, by store, by SKU — into your data warehouse or data lake, BI tool, planning solution and more.

AI-powered metrics and dashboards for consumer brands

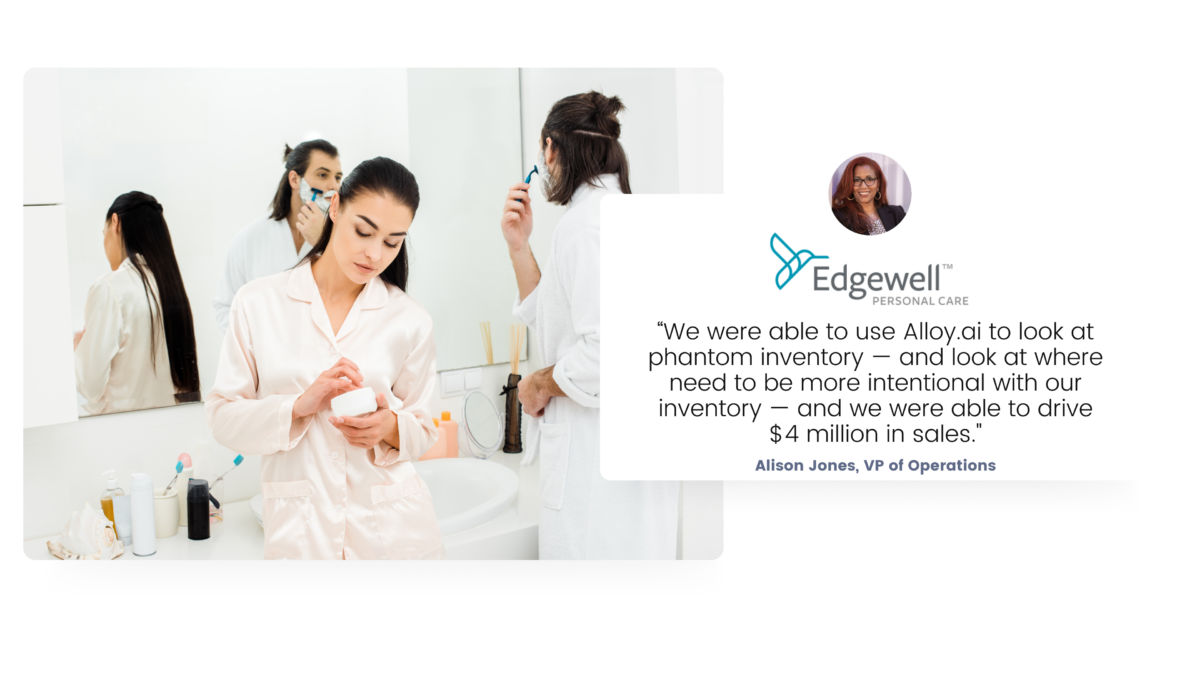

The data platform of choice for 100s of consumer brands

Across every category, leading consumer goods brands of all sizes trust Alloy.ai to connect and analyze the data they need to make critical sales, forecasting and supply chain decisions every day.

Your data security is our top priority

The Alloy.ai team never sleeps. We’ve got on-call coverage and a global team to make sure your data stays secure.

Google Cloud Platform provides

unparalleled security infrastructure for the cloud, from physical to operating systems.

Alloy.ai is native to GCP and leverages the platform end to end to achieve both scale and security that meets the most demanding enterprise needs.

SOC2 is a third-party evaluation on security, availability, processing integrity, confidentiality, and privacy. Alloy is SOC2 audited, with more information available upon request.

All data is always encrypted at rest, using industry standard encryption. Alloy.ai never shares your data with third parties.

All data is always encrypted in transit, using industry standard encryption. Data is only transmitted from destinations that you approve, and to destinations that you set up.

Permissions, user groups, data access policies, SSO and MFA – you have the full power of enterprise-grade security out of the box with Alloy.ai.

Alloy.ai prioritizes data protection, control and compliance with GDPR and CCPA.

Learn more about CPG data

Easy Ways to Use POS Data to Sell More and Avoid Inventory Problems

Manfred Reiche, subject matter expert in CPG data, joins the Alloy.ai Shelf Life Podcast to unpack intricacies of point-of-sale data, and shares a few easy ways to use it to solve sales and supply chain challenges.

Frequently Asked Questions

Read More

Alloy.ai Technical Overview

Gain a better understanding of Alloy’s architecture, integration, modeling, metrics and features in this Technical Overview.

Security at Alloy.ai

Data security is our top priority at Alloy.ai. Our platform maintains a SOC2 type II compliant with data encrypted at rest and in transit. Learn…

Bosch on building a successful sales strategy with POS data

Matthew Bergum from Bosch discusses how his team’s data-driven retail and ecommerce sales strategy relies on POS-data in Alloy.