Increase sell-in at Target and streamline order creation

Target Replenishment in Alloy.ai

Better replenishment can mean millions of dollars of incremental orders, but to stay on top of opportunities, you need to closely watch inventory levels, calculate correct order quantities, and then act quickly — all with the hope that Target’s Inventory Analyst accepts the order.

With Alloy.ai’s Target Replenishment Recommendations, consumer brands can identify new replenishment opportunities while saving hours spent hunting through spreadsheets.

Benefits of Retail Replenishment Recommendations in Alloy.ai

- Alerts for new retail replenishment opportunities - Get automatically alerted to new opportunities for incremental sell-in at Target to maximize sales and grow revenue. Retail Replenishment Recommendations automatically prioritize the replenishment opportunities with the biggest dollar impact first.

- Calculate the correct order quantities - Calculate the required order quantities, with controls and order constraints to adjust quickly.

- Leverage store-level data - Optimize network inventory with DC-level orders driven by store-level needs.

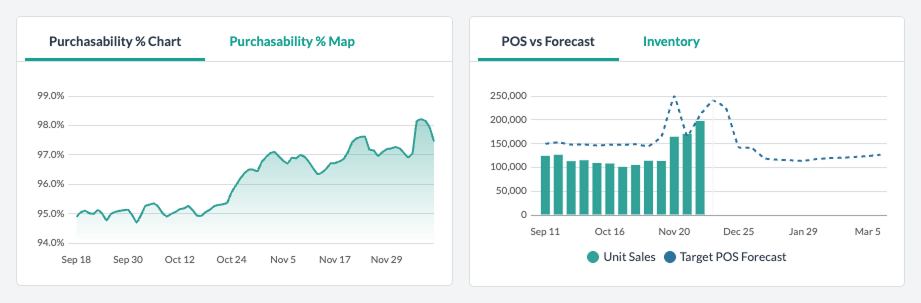

- Target-specific metrics - Alloy.ai builds your replenishment recommendations using Target-specific metrics like Target SPU, Target Purchasability, and Target POP forecast.

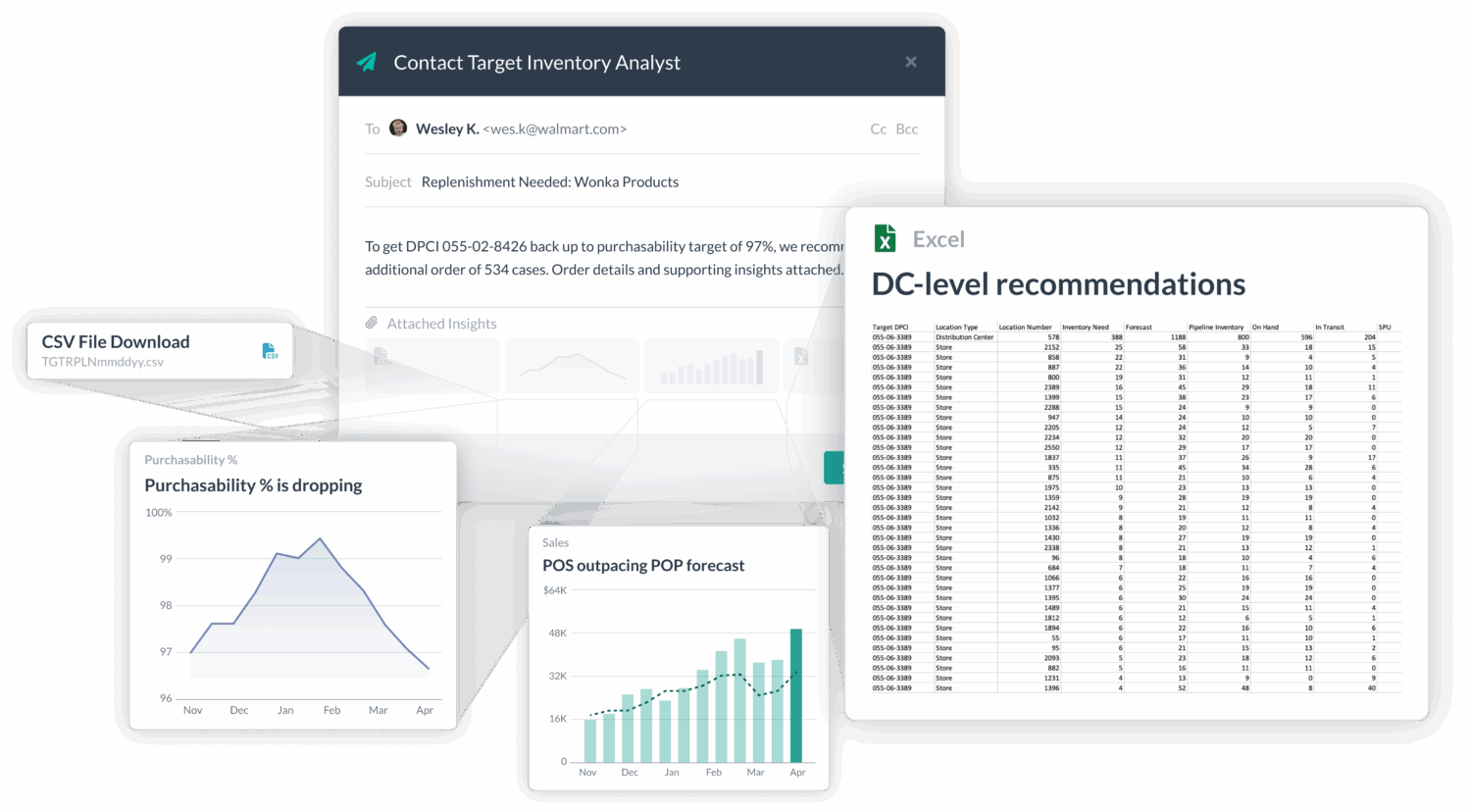

- Automatically generate an Excel template for the Target Inventory Analyst - Persuade your Target inventory analyst with clear insights. Ensure you notify them quickly when they are running low on inventory. Alloy.ai's features are purpose-built for Target suppliers, allowing you to download an auto-generated template for your order, alongside supporting data, that can be submitted directly to your Target inventory analyst.

Questions you can answer with Target Replenishment in Alloy.ai

- Which products are in need of additional replenishment?

- What incremental build orders should I recommend to my Replenishment Analysts and what data should I present to prove the need?

- Where are there opportunities to sell more?

- Which products and channels are at risk of losing sales in the near future due to OOSs?

- Do we have enough inventory at our warehouses to fill these recommendations?

- Where should we allocate if inventory is constrained?

Instant sales and inventory insights at your fingertips.

Book a Demo

Other ways Alloy.ai can help

- Forecast Adjustment Recommendations

- Retailer Forecast Monitoring

- Retailer Forecast Accuracy

- Lost Sales & Unconstrained Demand

Trusted by 100s of Consumer Brands

Frequently Asked Questions

What does Alloy’s Target replenishment solution do for suppliers?

Alloy provides actionable insights to prevent stock-outs and mitigate lost sales before they happen. The platform monitors POS and inventory data down to the store level (via Partners Online) to identify SKUs that require replenishment intervention. SKUs are ranked by incremental order value, and analysts can take action with just a few clicks by exporting order quantities by DC that are pre-populated into Target’s build order Excel template.

What makes Alloy’s approach better than manual ordering or Target's replenishment system?

Alloy uses ML to predict future sales down at the Store/SKU level and computes replenishment needs across all possible POS locations. By considering millions of data points every morning, the platform can identify incremental sales opportunities that are impossible with traditional, manual Excel sheets and would have otherwise gone unnoticed.

Meanwhile, Target’s algorithm determines replenishment at a rolled-up SKU/DC level, which can often lead to under-replenishing specific stores. This system is also susceptible to misconfiguration of various manually set parameters, exposing CPG Brands to thousands of lost sales revenue.

What data does Alloy need from me or Target to make accurate recommendations?

- Store POS and inventory

- Store Presentation Units

- Target’s POP POS Forecast

- DC Inventory and Units on Order

- Product Master information (Vendor Case Packs, SKU Price)

- Target WOS at the store and DC level

- Past and future promotional activity to influence POS Forecasts

How do I operationalize Alloy’s recommended orders with Target?

- Analysts pick SKUs from a list sorted by the biggest sales opportunity to begin building a replenishment order

- SKU/DC recommendations can be reviewed, and default parameters adjusted if needed

- Replenishment quantities are exported in a Target-provided Excel template, ready to be emailed or entered into the system

Can Alloy consider my own internal inventory to constrain the replenishment recommendations?

Yes, Alloy can ensure that a brand’s Sales team does not promise Target inventory that its supply chain cannot deliver! By integrating with a brand’s ERP data, Alloy’s recommended replenishment algorithm can be enhanced to work around existing inventory constraints. During allocation, Alloy utilizes specific logic to prioritize getting the limited inventory to the locations that need it most.